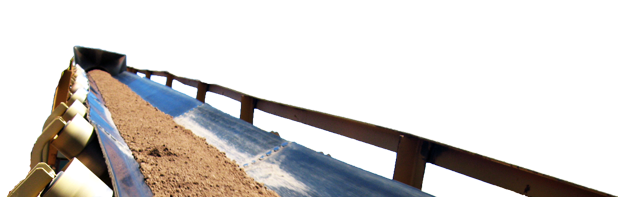

Stabilizer® Water Binding Technology

The only patented natural soil binder formulation. Derived from rapidly renewable organic materials, Stabilizer increases accessibility in natural aggregates. Many products call themselves “stabilizers” but this is the original natural binder trademarked over 30 years ago.

How does it work?

Integration - Blends into pore space of soil aggregate

Absorption - Absorbs 12 X its weight in water

Cohesion - Forms a cohesive gel that binds soil particles, keeping stability between soil particles during periods of excessive moisture

Balance - Maintains damp soil consistency longer when wet, and slowly releases moisture back into the soil in dry conditions

Stability - All of this equals a more stable and accessible footing for traffic

Related Products: Stabilizer | Original Stabilized Decomposed Granite